PCB Design and Fabrication:

The Need-to-Know Basics

Are you an electrical engineer on the brink of launching a new product? Need a custom Printed Circuit Board (PCB) but find the whole process a bit intimidating? You’re in the right place! In this user-friendly guide, we’ll break down the ABCs of PCB design, from software selection to material choice, manufacturing considerations, and more.

Powered by Gennex, your one-stop shop for semiconductors and electronics, we’ll help you navigate the path from idea to actuality with ease.

What is PCB Design and Fabrication?

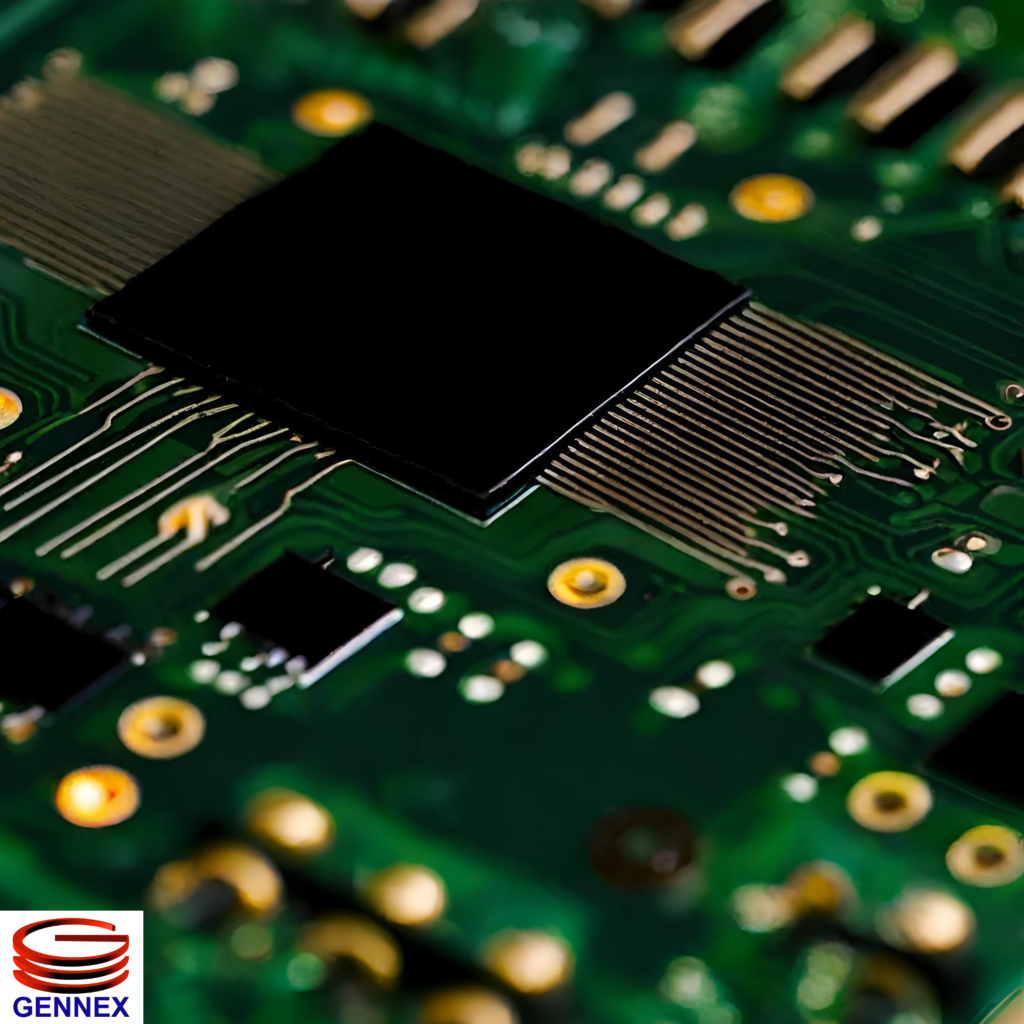

PCB design and fabrication is about creating the heart of electronic devices: Printed Circuit Boards (PCBs). These boards are brought to life by soldering components onto copper sheets layered on a non-conductive base.

The intricate design process is typically done using EDA software, and once the design is ready, it’s etched into a physical board. Given the complexity, many companies, like yours, trust specialists like Gennex. Our team manages the whole PCB production, working closely with you to optimize cost, quality, and performance.

Partner with Gennex for your PCB needs to avoid costly mistakes, accelerate your product’s launch, and ensure high-quality, reliable products. Let Gennex be your PCB solution.

PCB Design Tips and Best Practices

So, you have a circuit design and you’re all set to transform it into a printed circuit board (PCB). That’s awesome! But don’t rush into your design software just yet. There are a few things to remember.

- Start with a solid schematic. Ensure your schematic is sensible, neat, and has all the details needed for your PCB design. Remember, any mistakes here could lead to loss of time and money later on.

- Next, consider the size of your board and the number of layers. Figure out the smallest board size that can accommodate your components with ample space for traces and spacing. Think about whether a multi-layer board is needed for complex routing. More layers equal a higher cost, so only opt for this if it’s really necessary.

- When you’re laying out your board, place components in a logical fashion. Put related parts together and keep communication lines as short as possible. This will make your board easier to put together and troubleshoot.

- Manufacturability matters! Leave enough space around components for soldering and include markers for polarity and pin. Pick a board finish that fits your requirements. Also, go over design rules to ensure your board can actually be made.

- Do a test and review. Run design rule checks and visually inspect your board layout. Get a fresh pair of eyes to look over the design. Make necessary changes before sending the design to be fabricated.

If you plan carefully and follow best practices, you’ll end up with a PCB design that fulfills your needs, functions as planned, and can be manufactured without any issues. This means you’ll be able to get your product to market quicker.

Remember, the key lies in starting with a clear schematic and always bearing manufacturability in mind every step of the way.

Building PCBs That Perform and Scale: Why DFA and DFT Matter

Once your schematic is sound and your layout looks good, it’s time to think beyond functionality. How easy is your PCB to assemble, test, and scale for production?

That’s where Design for Assembly (DFA) and Design for Testability (DFT) come in. These essential principles help reduce manufacturing costs, minimize rework, and ensure long-term reliability.

- Streamlined Assembly: Proper component orientation, spacing, and standardized footprints reduce manual errors and speed up automated assembly.

- Faster Testing: Including test points and designing accessible probe locations allows for automated in-circuit testing (ICT) and easier debugging.

- Lower Costs: Efficient assembly and testing lower production costs and improve scalability.

Gennex’s engineers collaborate early in your design process to integrate DFA and DFT strategies. From recommending test pad placement to verifying silkscreen clarity and stencil design, we help make your PCB production-ready and inspection-friendly.

Whether you’re building a prototype or scaling up to full production, incorporating DFA/DFT ensures your product launches smoother and faster with fewer surprises.

Selecting the Right PCB Materials and Components

When designing a PCB, choosing the right materials and components is crucial. The substrate, copper, and solder mask you select will determine how well your board performs and how long it will last. For most consumer electronics, FR-4 fiberglass is a solid, cost-effective choice. It’s a flame-retardant epoxy resin combined with fiberglass that offers good mechanical and thermal stability. For higher frequency or power applications, consider materials like polyimide or ceramic.

For copper, 1 ounce (1 oz) copper is standard and suitable for most designs. For boards requiring higher current or that generate more heat, use 2 oz copper or thicker. The copper thickness, known as copper weight, is measured in ounces per square foot. More copper means lower resistance but also higher cost, so choose wisely based on your needs.

The solder mask is the coating that protects the copper traces between components. It comes in a variety of colors but green and red are most common. Make sure the solder mask you choose is compatible with your assembly process, especially if using lead-free solders. It should have good adhesion and insulation for your operating environment.

Components like integrated circuits (ICs), resistors, capacitors and connectors must match your board’s specs. Choose components with a suitable voltage and power rating, footprint, and pin configuration for your design. For the best performance, use high- quality components from reputable suppliers. Your circuit is only as good as its weakest component.

By selecting premium, high-performance materials suited to your application, your PCB will function reliably for years to come. If you need guidance on what works best for your specific design, PCB fabrication companies like Gennex offers material selection assistance and advice to help you make the right choices.

Why Choose Gennex for All Your PCB Needs

Gennex has been a leader in PCB design and fabrication for decades.

Gennex is your one-stop shop for all printed circuit board (PCB) requirements. Here are a few reasons why you should choose Gennex:

Experience and Expertise

With decades of experience, Gennex’ engineers are experts in PCB design and manufacturing. They stay up-to-date with the latest tools, software and technologies to design and produce high-quality PCBs. Their experience and expertise ensure your PCBs are designed and built to the highest standards. (See more about Semiconductor testing)

Quality and Reliability

Gennex demonstrates commitment to quality and continual improvement. They perform rigorous testing at multiple stages of the PCB production process to ensure high reliability and performance.

Customer Service

At Gennex, the customer comes first. They work closely with you to understand your needs, specifications and timelines. Their helpful staff provides guidance on design, budgeting and manufacturing recommendations to optimize your PCBs. They deliver on-time and keep you informed every step of the way.

Competitive Pricing

Gennex leverages their efficiency, expertise and high-volume production capabilities to offer competitive pricing. They provide budget-friendly prototyping as well as cost-effective production runs. You get the best value for your investment with Gennex.

For all your PCB design, fabrication and assembly requirements, choose the experienced, reliable, and affordable solutions from Gennex. They make the entire PCB process easy and help you bring your designs from concept to reality.

CHOOSE GENNEX FOR YOUR PCB SOLUTIONS

The key is finding the right partner who understands your product requirements and can deliver quality results on time.

With Gennex, you can have confidence that your PCB needs will be met, allowing you to focus on what you do best – innovation. Trust them to handle the rest.

Contact Gennex’ team through this link.