Your Trusted 24 Hours Business Service Provider !

One-Stop Source for Wafer Handling, Testing & Standard JEDEC Trays

In semiconductor manufacturing, every second counts and so does precision.

As your one-stop solutions partner, Gennex delivers a comprehensive range of wafer handling and packaging consumables like standard JEDEC trays.

We support both front-end processing and back-end IC packaging.

Core Wafer Products

Our wafer products support R&D, testing, and equipment simulation, enabling customers to meet application-specific needs across the semiconductor lifecycle:

Dummy Wafers & Test Wafers

These wafers are essential for equipment calibration, line setup, and thermal stress testing. Available in a range of diameters, they simulate production wafers without the cost of live silicon. We also support custom dummy wafer configurations tailored to unique tool sets or fab conditions.

Thermal Oxide Wafers

Used primarily for dielectric evaluations, it provides consistent results in process development. They're ideal for validating oxidation recipes and evaluating thermal conductivity in advanced nodes.

Photoresist wafers

Ideal for lithography training, process development, and simulation runs. They ensure reliable, repeatable results during photo alignment and etching process trials, helping fabs save time and reduce waste.

Daisy Chain Wafers

These wafers feature interconnected circuitry used to test the electrical reliability of packages. They support thermal cycling and high-speed signal validation. Daisy chain wafers are vital for engineers focused on interconnect performance and diagnostics.

Pattern Wafers & Diced Wafers

Pattern wafers support metrology calibration and overlay measurements. While diced wafers are suitable for packaging simulations and pick-and-place testing. Both offer precision cuts and surface uniformity to mimic real production conditions.

Improper handling leads to defects, downtime, and contamination.

Gennex helps eliminate those risks with wafer transport solutions:

FOUP (Front Opening Unified Pods)

These pods allow seamless wafer transfer under cleanroom

Class 1 conditions.

They ensure maximum cleanliness, minimize particle generation, and enable robotic integration.

FOSB (Front Opening Shipping Box)

These containers offer ESD protection and structural integrity for long-distance transport.

Designed with shock-absorbing materials, they protect against vibration and impact.

Wafer Cassettes

Our wafer cassettes are compatible with industry-standard equipment.

They support inspection stations, front-end processing, and material loading applications.

Wafer Shipping Boxes

Foam-lined and cleanroom-compatible, these boxes are ideal for prototype or small batch shipments.

They help prevent edge chipping and ensure safe transit between facilities.

Our logistics support across Southeast Asia allows for faster delivery, reduced freight costs, and lower buffer stock requirements. This makes Gennex your trusted Asia-based wafer supplier.

After wafers are diced, packaging becomes critical to product integrity. Gennex provides backend packaging solutions engineered to meet high-mix, high-speed manufacturing demands:

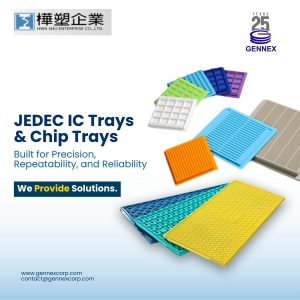

Standard JEDEC Trays

Gennex offers over 2,500 standard JEDEC trays for IC packaging and automated handling. These trays simplify qualification, ensure compatibility with standard handlers, and support high-speed packaging lines. JEDEC-compliant trays reduce variability and improve traceability.

Chip Trays

Primarily designed for the secure handling and storage of small form-factor Integrated Circuits (ICs). Our anti-static chip trays protect against ESD damage while maintaining tight dimensional tolerances. These are critical for precision placement and automated processes.

Carrier Tape & Reel

As a carrier tape and reel supplier, we support custom pocket designs tailored for a wide range of IC sizes and shapes. Our tape and reel solutions are ideal for small lot production, and mass packaging alike.

Gennex works with trusted partners like Hwa Shu Enterprise to produce our products. This ensures consistent quality and ESD protection across the entire supply chain.

Why Partner with Gennex?

Procurement professionals and engineers face unique challenges in this niche category. Such as sourcing from overseas suppliers who may not align with local specs or naming conventions.

At Gennex, we simplify the process:

- Technical Guidance: We ask the right questions upfront, avoiding mismatches and delays. Whether you’re sourcing a custom dummy wafer or selecting the correct standard JEDEC tray, we help provide solutions.

- Asia-Based Supply Chain: With strong regional support, we ensure responsive delivery, local support, and reduced shipping risk.

- Flexible MOQ Support: We offer cost-effective options for every stage of your manufacturing cycle from prototyping to production

Gennex supports your sourcing with local expertise, fast logistics, and JEDEC-standard products.

Looking to reduce sourcing risks and improve spec alignment for wafer consumables?

Contact us today at contact@gennexcorp.com to learn how we can support your wafer needs.

FAQ on Your Wafer Handling & Packaging Needs

Gennex combines engineering consultation, regional logistics, and supplier flexibility to support semiconductor teams regionally. Our wide product portfolio, from dummy wafers to packaging consumables — helps streamline procurement and reduce operational risk.

With more than 2,500 JEDEC IC tray open tooling, Gennex makes it easy to find the right tray for your packaging and automation needs. We also support spec matching and customization for non-standard components.

Yes. Gennex provides custom dummy wafers tailored to your tool size, thickness, and material requirements. Please contact our tech experts at contact@gennexcorp.com to ensure the wafers match your exact specifications.

Gennex offers a full range of wafer shipping boxes, FOUPs, FOSBs, and wafer cassettes — all cleanroom-ready and ESD-safe. Our regional inventory allows faster delivery and reduces freight risk for time-sensitive projects.

Our team at Gennex offers expert guidance to match wafer cassettes to your equipment and wafer size. For more information, please reach out to our team at contact@gennexcorp.com