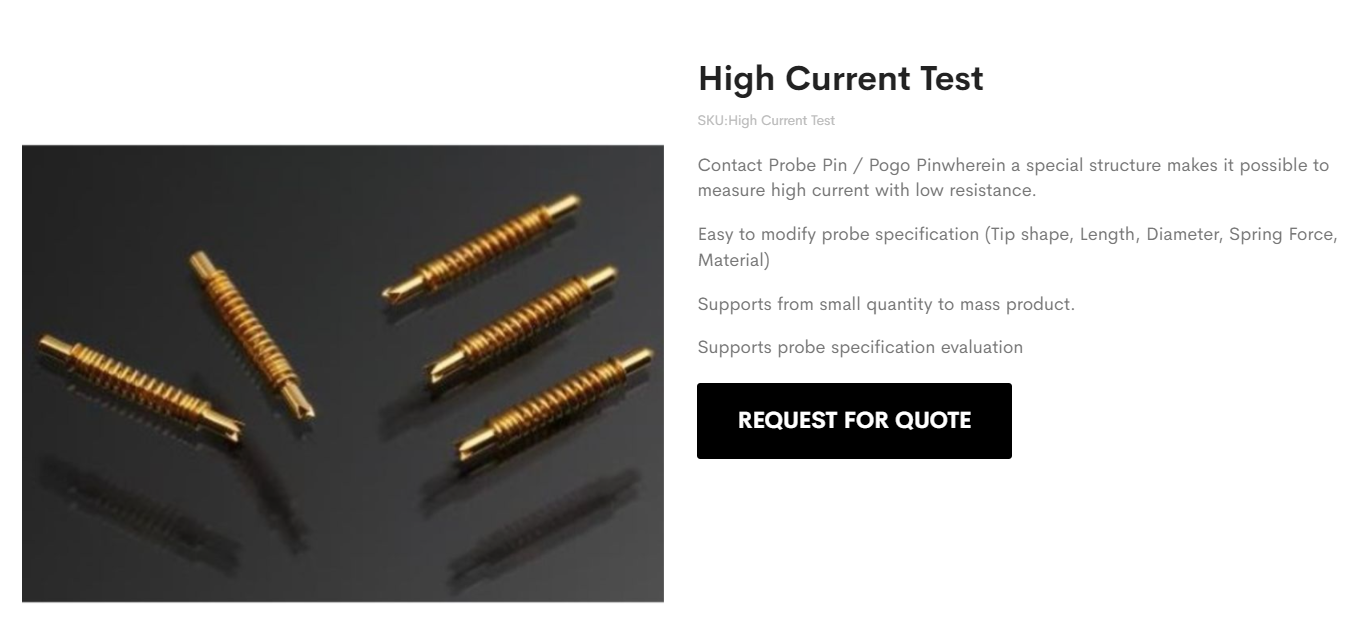

What Are Pogo Pins and How Do They Work?

Pogo Pins, also called Spring Loaded Pins are pins that connect two surfaces temporarily with the help of a spring. The plunger moves in and out of the barrel when pressure is applied, thanks to the spring. When pressure is released, the plunger goes back inside the barrel.

- Size Considerations: Choose pin sizes that are appropriate for the component density and current requirements of your application.

- Material Matters: Select from materials like beryllium copper or stainless steel based on conductivity needs and environmental conditions.

- Plating Preferences: Gold plating offers superior conductivity and corrosion resistance, whereas nickel plating is a cost-effective alternative.

- Spring Force: Determine the necessary force for your application to ensure effective contact without risking damage to the contact surface.

Utilizing Pogo Pins Effectively:

To achieve dependable testing results, it’s crucial to:

- Secure the pogo pins firmly within the test fixture for unwavering contact.

- Keep the pins clean, free from contaminants that may hinder conductivity.

- Apply consistent pressure to ensure a solid electrical connection without causing damage.

- Avoid pin deflection to maintain connection integrity and test accuracy.

By adhering to these guidelines, professionals can leverage the full potential of pins for reliable and accurate testing outcomes.

Key Benefits of Using Pogo Pins for Testing

- Convenience and Ease of Use

- Cost Effective

- Long Service Life

- Low Contact Resistance

- Versatility

Choosing the Best Spring Loaded Pins for Your Application

Size

The size of the pins you choose depends on your application and device. For printed circuit boards with high density components, you’ll want smaller pins, like 0.5 to 0.8 mm in diameter. Larger pins, 1.0 to 2.0 mm, are good for applications where you need to pass higher currents. In general, the larger the pin, the higher the current it can handle.

Material

The material of the pins is also important.

- Spring pins come in beryllium copper, phosphor bronze, and stainless steel.

- Beryllium copper is the most common and provides good conductivity and corrosion resistance.

- Stainless steel pins are more durable and better for high-temperature applications.

Consider your operating environment and how much stress the pins will be under to determine the best material.

Plating

Many pogo pins have gold or nickel plating over the base metal.

- Gold plating provides the best conductivity and corrosion resistance, but it is more expensive.

- Nickel plating is more affordable but may corrode over time.

For most applications, gold plating of at least 0.5 to 1.0 microns thick is a good choice. Check how many insertions the gold plating is rated for based on your application. Contact our Technical Engineers for free assistance.

Extension Force

The extension force refers to how much force the pin exerts when extending to make contact. A pin with a higher extension force, around 30 to 60 grams, is good for applications where you need to pierce through oxidation or debris on the contact surface. Lower extension forces, around 10 to 30 grams, are suitable for most standard applications. An extension force that is too high could damage the contact surface, so choose a pin with an appropriate force for your needs.

To determine which is the best fit for your particular application:

- Consider the size

- Material, plating

- Extension force of the pogo pins

Choosing high-quality pins designed for your needs will help ensure reliable and long-lasting electrical connections.

Where can I find Pogo Pins?

You can purchase pogo pins from electronics distributors and interconnect component suppliers. Look for manufacturers and brands that are reputable and offer high quality, precision-made parts.

For the best results, choose pogo pins that are specifically designed for your intended application, such as IC testing, PCB testing or programming headers.

When it comes to sourcing electronic and semiconductor components, including the versatile pogo pins, Gennex stands out as a comprehensive solution provider.

Choosing Gennex as your trusted pogo pin distributor means partnering with a company that prioritizes quality, offers PCB design and fabrication services, and provides responsive support through a strategically positioned network.

How do I check Pogo Pin quality?

When evaluating pogo pins, consider factors like:

- Plating material: Gold plating provides the best conductivity and corrosion resistance for most applications.

- Plunger and barrel material: Stainless steel or beryllium copper offer good spring performance and durability.

- Plating thickness: Thicker plating, e.g. 30-50 microinches, will allow for more mating cycles.

- Spring force: 30 to 40gFis typical; higher forces may damage sensitive circuits.

- Travel distance: 0.5-2 mm is common; choose based on your board thickness and geometry.

Using high quality pogo pins will help ensure reliable connectivity and long service life for your testing and programming needs. With proper selection and care, pogo pins can provide many thousands of trouble-free mating cycles.

Why Choose Gennex as your trusted distributor of Pogo Pins

Gennex is more than just a distributor of electronics and semiconductor components—we’re your partners in innovation.

We pride ourselves on our skill in crafting top-tier printed circuit boards (PCBs), delivering a comprehensive package tailored to your electronic requirements. (Click here to know more about PCB Design and Fabrication)

We offer test sockets and pins solutions depending on the customers’ requirements. Renowned for our quality pogo pins, PCB design and fabrication. Our responsive, experienced team is ready to provide the perfect pogo pin solution for your project’s demands.

Our strategic locations in key Asian markets like Singapore, the Philippines, Thailand, Vietnam, and Malaysia amplify Gennex’ commitment to outstanding service. This ensures you get quick, localized support, fast deliveries, and a top-tier customer experience. Contact us now!